Beyond hops, malt, yeast and water

Germany is a proud beer country. Production and consumption have a long tradition here, which is reflected, for example, in the often-cited purity law. But beyond these regulations, a field of interesting beer beverages has developed, such as fruit beer. As good as the purity law sounds, it not only ensures quality, but also severely restricts the spectrum of beer drinks. Why should a beer to which other ingredients are added be worse per se?

We have developed“bitter sweet“. Unfortunately, there is no word known to us in German that so unites the supposed contrast of sweet and bitter. Because it is more than just the composition of two tastes or words in one word. It’s about love and pain, as countless songs sing about in bittersweet harmonies.

Since music is such an important source of inspiration for us in our work at the Innovation Lab, we would like to take this opportunity to mention our unique MILK. Spotify Playlist. A list of collected works that all have one thing in common: taste not only in music, but even in the title of the song, album or the name of the performers. Enjoy this feast for the ears!

But now back to the topic: fruit beer! A little sweet and a little bitter.

Good beer even without purity law

In other countries like Belgium there are traditional beers like Lambic, which have nothing to do with the Purity Law or with bad beer. We have been inspired by this tradition and generally by fruit beers in order to produce a beer drink with little alcohol but a lot of flavor.

Shower with shower-t

This isn’t the first time we’ve brewed something together, but so far we’ve been all about mead or ginger bug. Beer is still a new field for us and we use a brewing kit for our first experiments. It contains all the important utensils and also all the essential raw materials except beet and apple, which give our beer that special something. Once again, and as always with alcohol, we are talking about fermentation. More specifically, about the conversion of sugar into alcohol. In the case of beer, this comes from malted grain and, in the case of fruit beer, also from fruit.

The way of the beer

The first step in beer production, both small and large, is mashing. Here we want to extract the sugar from the malt, which is later converted to alcohol. In addition, sugar comes from apples. We juice fresh apples, we heat the obtained juice (4 liters) to 72 degrees and stir in the malt grist. This step in the process is also called mashing in. For the next 60 minutes, we cook out the sugar at a temperature between 65 degrees and 69 degrees. Finally, we heat the mash to 78 degrees, this process is also called mashing off. In the next step, we separate the resulting wort from the malt, for this we pour everything through a coarse sieve. The smell and taste of the wort is sweetish and has a strong malt flavor. To dissolve as much sugar as possible from the malt, we boil 3 liters of water.

We rinse the malt through with the so-called “pouring”, which has a temperature of 78 degrees. The malt lies firmly in the sieve and thus forms a natural filter, through which the water gradually seeps through. We now add the hops to the wort. This step is also called “boiling the hops”. The hops are in pressed pellets and have a very aromatic smell. We divide the hops into three parts and add the first part after 10 minutes of cooking time and the other two parts after 50 minutes of cooking time.

After 60 minutes of boiling, we quickly cool down the wort, this is done in a large ice water bath. The cooled cloudy wort looks visually somewhat unappetizing. I wonder if this will be a tasty beer? – In any case, appearance and taste are not dependent parameters and Ugly Delicious is therefore a fixed concept.

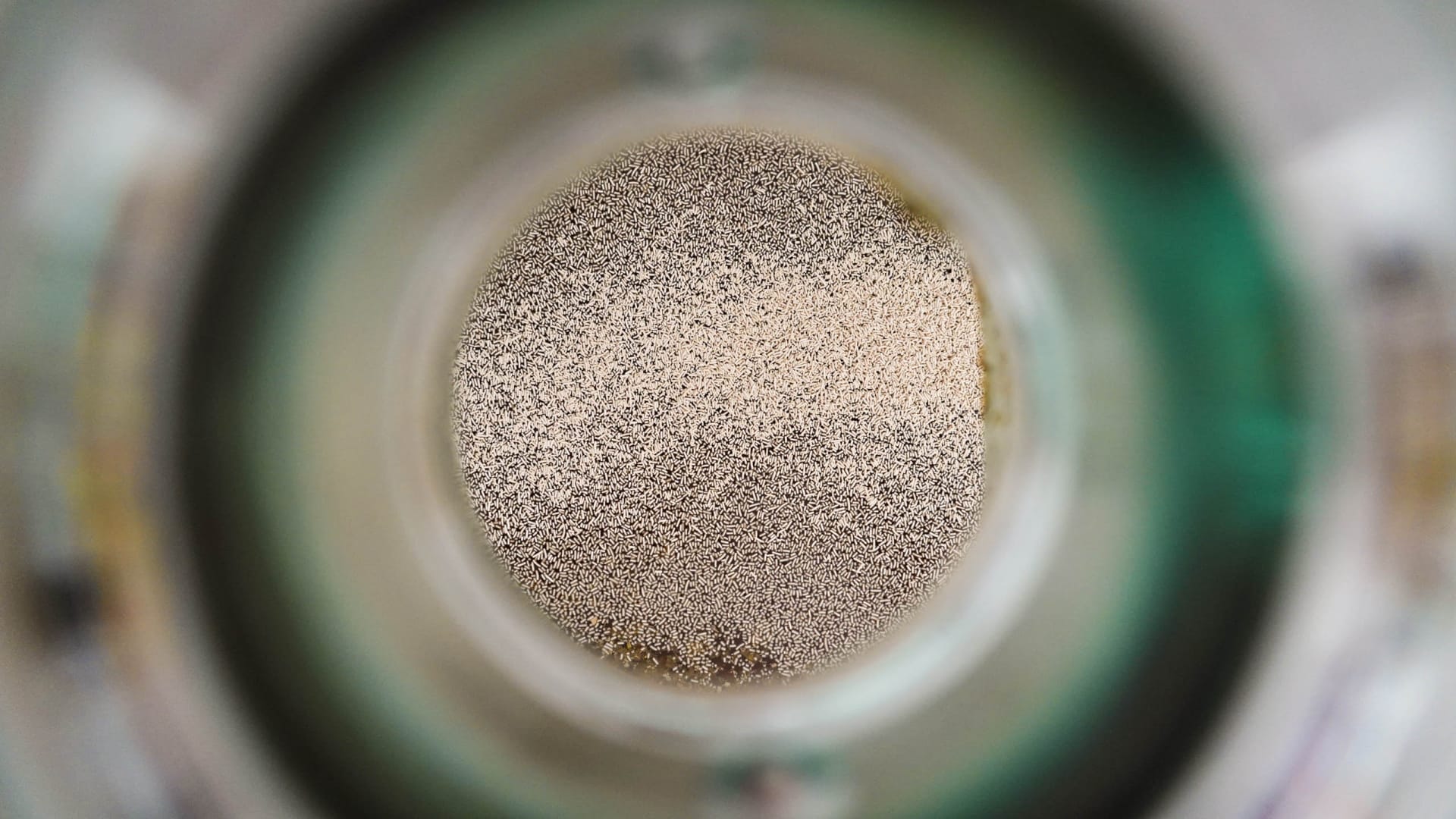

In the next step, we sterilize the fermentation balloon and the funnel for filling. We then fill the wort into the fermentation balloon and add the yeast. It looks like dry yeast when baking cakes, but it’s a special brewer’s yeast because we neither brew nor bake. Whereby baking and brewing are historically closely linked. Incidentally, Lambic is fermented spontaneously and made without added yeast. This process is more complex and difficult to control, so we rely on brewer’s yeast.

After we have added the yeast to the wort, we swing the fermentation balloon vigorously. We close the fermentation balloon with a stopper in which a fermentation tube (airlock) is inserted. Over the next few days the yeast will multiply and convert sugar into alcohol, and it will bubble vigorously during this process. This creates CO₂, which can escape through the fermentation bung. The CO₂ can get out, but no air or foreign yeast can get in.

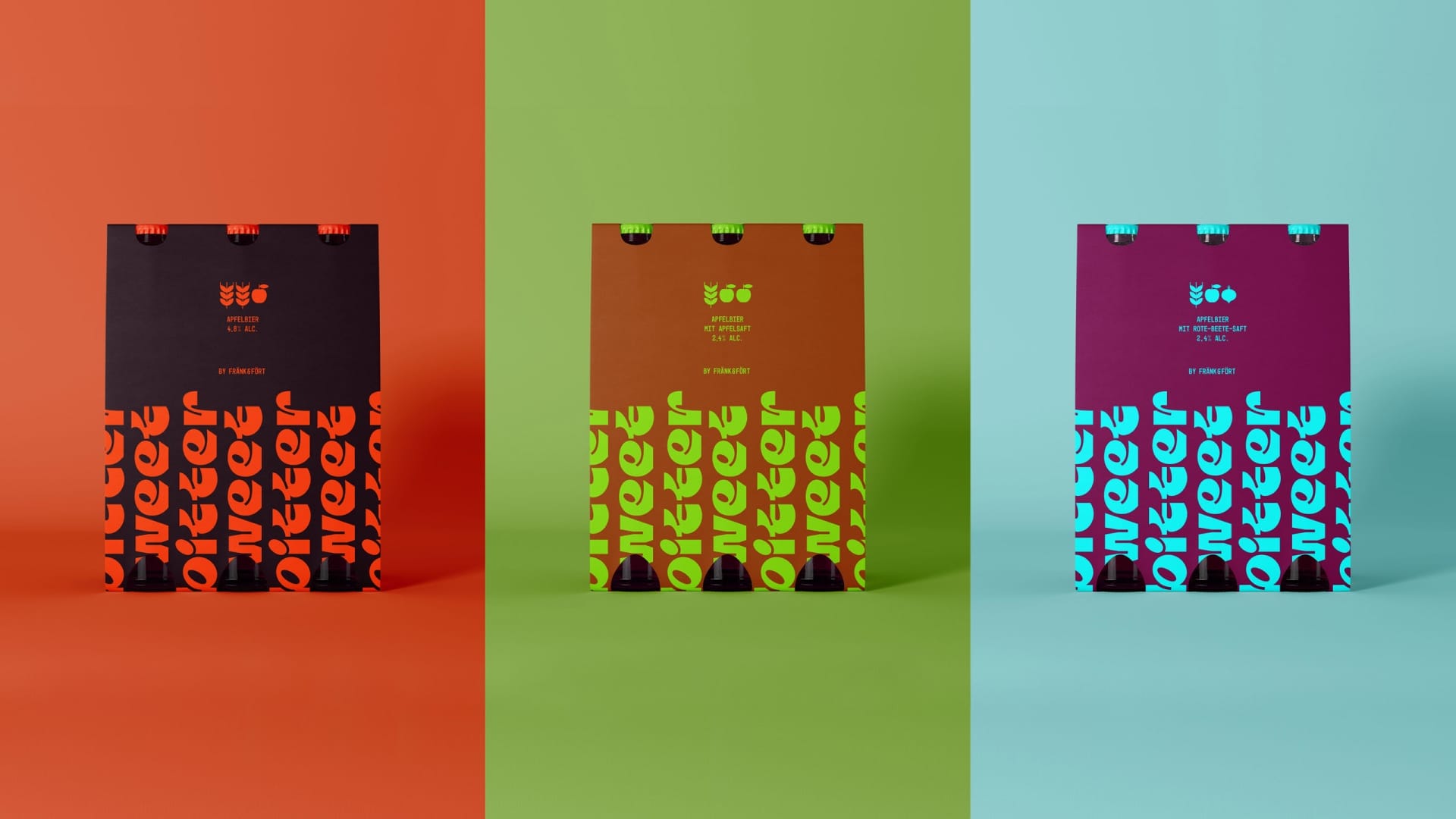

One beer – Three flavors

Fermentation is complete after about two weeks. We draw off the beer with the help of a beer pump and divide the liquid into three parts. The first part remains pure dark apple beer, the second part is stretched to the same extent with apple juice and the third part is also stretched to the same extent with beetroot juice. In this way we reduce the alcohol content and bring a different taste to the beer.

Apple beer (natural)

Apple beer (+ apple juice)

Beetroot – apple beer (+ beetroot juice)

Das Bier füllen wir in 0,33 Longneck Flaschen ab. Damit die Hefe bei der Flaschenreifung Kohlensäure im Bier erzeugt, müssen wir der Hefe Futter geben. In dem Fall ist Futter gleich Zucker. Den Zucker geben wir nur beim bereits vergärten Natur-Apfelbier hinzu. Die Zugabe von frischem Apfelsaft und Rote Bete-Saft in den gestreckten Bieren müsste genug natürlichen Zucker für die optimale Kohlensäureentwicklung einbringen. Wir verschließen die Bierflaschen mit handelsüblichen Kronkorken und lassen es für vier Wochen bei Zimmertemperatur reifen. Anschließend lagern wir es im Kühlschrank.

Cheers.