Fibers on the rise

Cartonboard solutions are currently more popular than ever – not least thanks to PPWR & Co. Fiberization is progressing, with successful companies such as the MM Group leading the way. On innovation and ambition in the world of cartons Andreas Macku, Innovation Director for Food & Specialties, answered our questions.

MILK: Do you feel the growing demand? And how do you ensure that your products are “regulation-ready”?

Andreas Macku: Yes, absolutely – the demand for paper-based packaging has increased significantly in recent years. In the consumer goods sector in particular, we see that brands are increasingly looking for sustainable solutions, and cartonboard folding cartons are particularly in demand. We have experts in the company who are very closely involved in developments at EU level and beyond. They always keep our group up to date when it comes to new regulations or planned legislative changes. As a result, our development teams know exactly what is important in terms of design and can provide our customers with the best possible support to ensure that the end product is truly “regulation-ready”. We are also in constant contact with relevant associations and initiatives. This not only helps us to identify requirements at an early stage, but also to play an active role in shaping them – which is a real advantage, especially in such a dynamic phase as the current one.

MILK.: We often see the need to switch from plastic solutions to fiber-based solutions. How do you support customers in this process?

Andreas Macku: For us, the focus is always on the right packaging approach for the respective application. Not every product can be sensibly converted into a paper solution – which is why realistic expectation management and transparent communication with the customer are essential. At the same time, we do not want to restrict our view and remain open to innovative approaches in all directions. Where it makes sense, we provide our customers with holistic support throughout the changeover process – from the initial requirements analysis, concept development, design, material selection and prototyping through to testing, validation, production and implementation. We work closely with our customers on an interdisciplinary basis to find the best possible solution – both functionally and in terms of sustainability.

MILK.: Barrier papers are currently particularly popular for use in the F&B industry – how do you rate this development? What are the advantages and disadvantages of barrier papers compared to plastic solutions?

Andreas Macku: Barrier papers are currently a very exciting option for many applications in the F&B industry. Their great potential lies above all in the possibility of reducing plastic content and relying on renewable raw materials. Especially if the barrier papers are recyclable – ideally in the paper waste stream – they can demonstrate their sustainability advantages over traditional plastic packaging.

Nevertheless, we must remain realistic: Barrier papers cannot replace plastics equally in all areas. Especially when it comes to very high demands on barrier properties, such as for coffee or products that are sensitive to fat and oxygen, they are still reaching their technical limits. Product protection – and therefore also the best-before date – must not suffer as a result of the packaging solution, as food waste is often more serious from a sustainability perspective than the packaging itself.

MILK: What role does sustainability play in the procurement of your raw materials?

Andreas Macku: Sustainability is not an additional topic for us, but a central component of our procurement strategy. We consistently rely on certified, deforestation-free wood and fiber sources – for example in accordance with FSC® or PEFC standards. This gives us and our customers the assurance that the materials come from responsible sources. At the same time, we attach great importance to clear requirements for our suppliers – not only in terms of environmental standards, but also with regard to issues such as human rights, working conditions and compliance. These standards are firmly anchored and are regularly reviewed.

MILK.: Cardboard packaging is already perceived as very sustainable. However, you are aiming for a comprehensive sustainability strategy that goes beyond the product. What sustainable practices have you implemented in your production in recent years?

Andreas Macku: That’s right – paper packaging inherently has a good sustainability image. However, it has always been clear to us that real sustainability goes further than just the product. That’s why we’ve been working for years to make our production more sustainable. A central focus here is on decarbonization.

We have set ourselves ambitious climate targets as part of the Science Based Targets initiative and work with an internal CO₂ price, among other things, to steer investments specifically towards lower-emission technologies. At the same time, we are continuously increasing the proportion of renewable energy at our sites.

We also focus on the circular economy when it comes to water: water is already reused in many of our plants, and modern wastewater treatment plants ensure efficient and environmentally friendly treatment. The first sites have already been certified according to recognized water management standards.

We also systematically promote waste avoidance – through process optimization, material efficiency and intelligent recycling of production waste. Our claim is clear: sustainability must be tangible and measurable along the entire value chain – even behind the scenes.

MILK: You also develop innovative products yourselves – how does your development process work?

Andreas Macku: For us, the focus is not on the individual ingenious developer, but on a strongly networked team. In our MM Innovation Network, we pool the expertise from various areas of the MM Group in order to develop the best possible solutions together. This includes our six cartonboard and paper mills, 54 packaging sites worldwide and teams of experts from the areas of Sustainability & Product Safety, Sales & Marketing, Market Intelligence, Patent Management, Technology and, of course, our Pack Development Centers.

Our development process follows two approaches:

On the one hand, PULL innovations, in which we implement customer-specific briefings in a creative and targeted manner – often in close co-creation with our customers. Secondly, PUSH innovations, which are proactively developed within our network, respond to market trends or sustainability issues and are then brought to market maturity.

MILK: What are the most exciting new developments in your portfolio that are of particular interest to food manufacturers?

Andreas Macku: This is where my innovation packaging motto comes into play: “For me, a packaging project is finished when I can buy the product in the supermarket.”

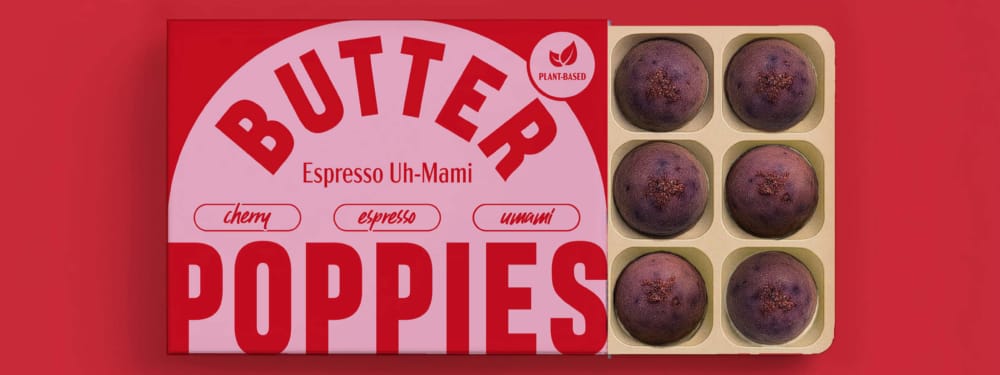

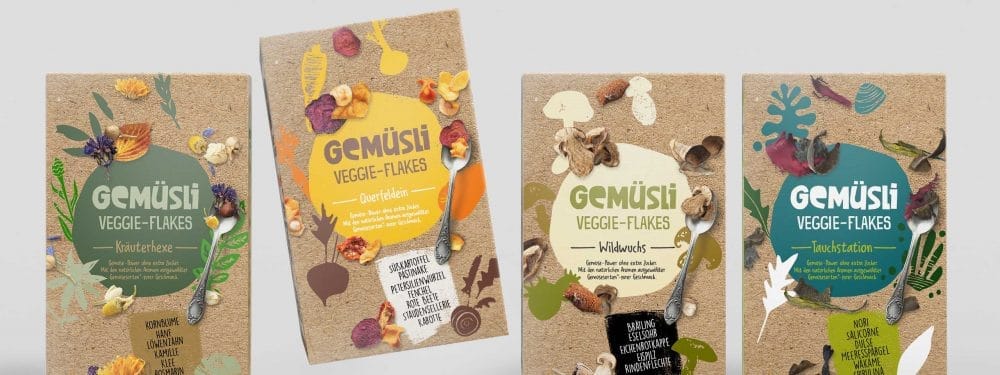

We have many new developments that have been successfully launched and are already on the market.

GreenPeel is an innovative tray design that uses up to 90% less plastic than conventional plastic trays. We achieve this through a particularly lightweight design and the targeted use of minimal amounts of material. Sustainability shouldn’t be complicated – that’s why we developed GreenPeel so that it can be seamlessly integrated into existing processes.

The continuous flat edge and the flat base make it easy to use in most standard packaging, production and sealing systems. Another new development is the MM CartonCavity system. CartonCavity is an innovative cartonboard solution that replaces conventional plastic trays and blister packs.

The system consists of a passe-partout frame and individual cavities that securely hold the product in place while presenting it in a high-quality manner. CartonCavity is a real game changer. It combines ecological responsibility with functional design and offers companies a sustainable alternative to plastic packaging.

We have further new developments in the Fruit&Vegetable, Beverage and Confectionery segments. I am particularly proud of our new MM Moulded Pulp line. The Moulded Pulp solution uses thermoformed wet-moulding technology – a breakthrough in the processing of fiber materials. This enables us to create packaging for demanding industries such as food, pharmaceuticals, personal care and more.

MILK: Does the MM Group have any special initiatives to accelerate the circular economy?

Andreas Macku: Yes, definitely. We are actively involved in the Senate of the Circular Economy – a cross-company alliance in Austria that pursues the goal of advancing the circular economy holistically and across all sectors. As a leading manufacturer of fiber-based packaging, we contribute our perspective and expertise in a targeted manner – in exchange with retailers, bottlers, disposal companies and political decision-makers. Dialogue at eye level is particularly important to us, as a functioning circular economy requires close cooperation along the entire value chain. Such initiatives are an important lever for us not only to improve internally, but also to help shape structural changes at system level.

Andreas Macku is Innovation Director for Food & Specialties at the MM Group, headquartered in Vienna. The MM Group is a leading supplier of sustainable paper and cartonboard packaging for consumer goods – and focuses on innovation in order to have a positive impact on the environment and society.

More exciting paper projects and concepts can be found here in the magazine!