Can mushrooms be used to establish a new food system?

Mushlabs is up to something just like this. What sounds like mushrooms from the laboratory combines traditional food culture with state-of-the-art production techniques. The result is not only an alternative to meat, but the potential to make our food production fundamentally more sustainable.

Cathy Hutz studied business psychology and food product development and has worked in the Fermentation Lab first at Geranium restaurant and then at Noma (two of the best restaurants in the world, both located in Copenhagen) where, together with David Zilber, she was able to live out her enthusiasm for fermentation at the highest culinary level. That’s exactly what she does now as VP of Product at Mushlabs. We talked to her about what exactly she does and what kind of product it actually is. Together with Antje de Vries she has written a book about fermentation, by the way, who wants to deal with it himself should definitely read it!

A new staple

Who is or what does Mushlabs do and what is your job there?

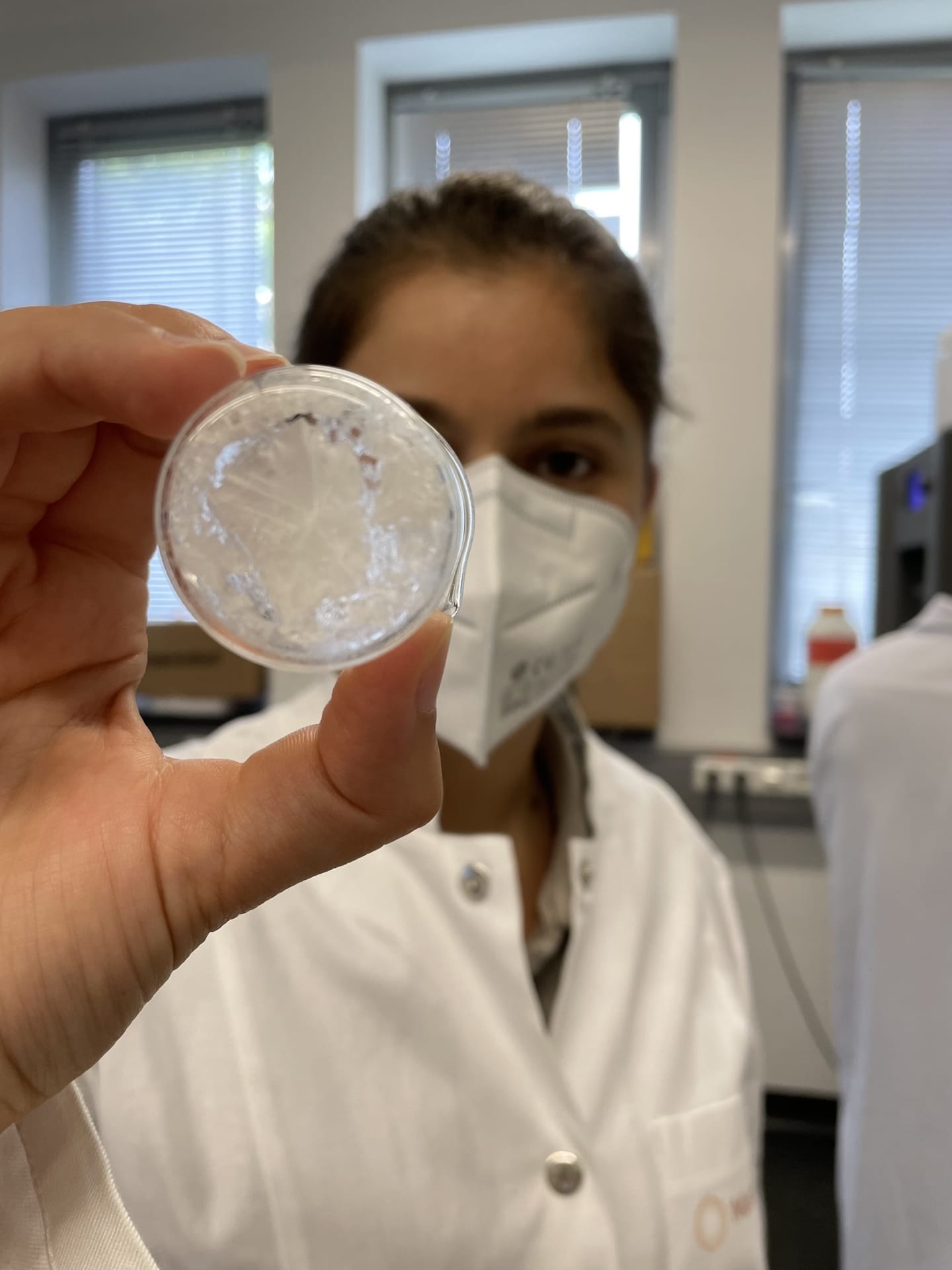

Mushlabs is a young biotechnology company from Hamburg, Germany, working on the next generation of sustainable food using edible mushrooms and fermentation. In fermenters, mushroom mycelium (filamentous cells that are normally found in the soil, i.e. below the fruiting body that we mean when we talk about mushrooms ) is cultivated. This process requires significantly fewer resources such as land, water or energy than the production of other meat substitutes. Production takes place vertically in the fermenter in a small space. The process is highly efficient and fast, requires hardly any land, no arable land, no pesticides or fertilizers – through all this, biodiversity is promoted. Mushlabs is also working to add value to by-products from the agri-food industry (known as sidestreams) and incorporate them into production as feed for the mushrooms, which increases sustainability, efficiency and value in the food system and offers a major contribution to a circular economy.

The process is very efficient, already after a few days can be harvested mycelium. By using food industry sidestreams, fungi then do for us exactly what they do in nature: break down or convert organic material from plants and animals. Whereby we currently only work with vegetable by-products. (Fungi, by the way, form their own kingdom along with animals and plants ). After harvesting the mycelium, I take care of the application areas. Mycelium is basically a completely new raw product. For me, the process is comparable to that of winemaking, supplemented by the aspect of texture. We have therefore developed a process that allows us to influence the end product in a controlled and targeted manner in a wide variety of ways as early as the fermentation stage. For us, this opens up endless possibilities, which is insanely exciting.

How did fungi, or rather mycelium and fermentation, come to be the answer to pressing questions of human nutrition? Was this approach already present?

Yes, the procedure has been known for some time and mycelium is not something entirely new in the food sector. Quorn, for example, is a comparable product, but it is based on molds, whereas we grow mycelium from edible mushrooms. Mycelium is also used in biotechnology for the production of specific nutrients or enzymes. The process is well known but we now use the whole mycelium instead of extracting proteins and extruding them, which makes our products particularly natural. We also use by-products as a nutrient base. It is important to us to use the whole product, because mycelium has a very good nutritional profile, is rich in fiber, among other things, which is good for intestinal health. Fiber is consumed far too little, while proteins are sufficiently available and consumed in our country.

Fermentation offers us humans the possibility to ideally control the growth of microorganisms. Basically, our process is comparable to brewing beer. Fermentation is closely controlled in both cases to obtain a specific result. At the same time, there is also fermentation that occurs in an uncontrolled manner. The process itself is always a natural process, but it can be precisely controlled.

Rethinking food with fermentation

With numerous start ups working with fermentation, many seem to have been working towards new applications of this ancient technique for some time. (QOA, WNWN Food Labs, At Last/MyForest, Quorn, Formo/Legendairy, Solein, Air Food…. )

Fermentation has always been an important process for food production, just think of wine, beer, cheese… which accordingly has been used by food producers for centuries. These, along with universities, have had exclusive access to complex fermentation technology and have built up a great deal of knowledge. Today, you can get the money you need for plants through investors and implement your own ideas. It’s a huge playground. Through startups, the application is liberalized, innovated and sustainably oriented, because much is thought and produced outside of classic paths.

Restaurants drive innovation

At the same time, many restaurants have also discovered this technology for themselves. You worked in the Noma Fermentation Lab yourself. What role does gastronomy play in the current fermentation hype?

Here the subject was demystified. It’s not always just “Rocket Science”, it’s about natural processes that can be approached in a somewhat shirt-sleeved way. New ideas were not only introduced by academics or in a scientific context. Certain problems are thereby eliminated, allowing freer action and breaking down boundaries. Gastronomy has definitely played a role here also in other areas such as diversity of varieties etc. it is often restaurateurs who generate attention by taking on such issues and communicating them to their guests, the media and other restaurateurs.

Your former colleague David Zilber is also now no longer working in a restaurant, but in the food industry. Is this how restaurateurs are revolutionizing the food world? Or rather, what made you decide to leave gastronomy behind?

The industry has certainly recognized that such individuals bring added value and think out of the box, for example. It is precisely the bridge from high-tech processes to foods that must function emotionally that has long been overlooked. Startups are also trusted more than global corporations, some of which have exploited the planet and overengineered processes with highly industrialized and technologized approaches. Unfortunately, there has also been a lot of consumer deception, which has led to a lasting breach of trust.

Was it an important motivation for you to be able to move bigger levers in the food industry instead of feeding a small exclusive circle in a restaurant?

Yes, totally – the prospect of not just making 50 people happy, but making a difference on a broad scale is very motivating. Our products can be made with regional sidestreams. This allows by-products to be used worldwide to produce food. For me, that’s an important aspect, but restaurateurs trigger a ripple effect as messengers, so that’s important too, of course.

To what extent were you prepared for your job by working in the Fermentation Lab at Noma? Which aspects are also important here and what is completely different and new?

Quite a lot is new and challenging. The main learning was to get the right people on the team. Noma has limited itself (to ingredients from the Nordic hemisphere) and therefore had to relearn many things and just get creative. Such an open and creative approach is what I learned at Noma, and I’m sure it helps me now.

Pleasure as a key

Can you say anything else about your culinary processes? How important is pleasure in your development?

Our products must taste good, that is the most important thing. We work with many chefs for this and are very interested in their feedback. Mycelium naturally contains a lot of umami, a natural, savory and full-bodied flavor that is also known from meat and cheese. From this basis we go further and develop suitable seasonings. Seeing chefs work with a new type of raw material is very special and exciting, also because we have the opportunity to adapt the product through our fermentation processes. The whole thing has a very high culinary content.

When are Mushlabs products available in the supermarket? What products and applications can we expect?

That depends on Novel Food approval, which is pending. As soon as we have a release, we are also on the market. We are already in contact with the relevant partners for this. They are very interested in our product, a soy-free meat substitute that can be produced regionally. Among other things, we are currently working on “meatballs” but also some other products.

Many alternative products are very expensive at the beginning, (scaling, development costs…) can you already say something about the price range?

We will position ourselves in the range of other vegetable alternatives and definitely be competitive.

And how could your products be packaged? Have you already thought about this?

We think about it a lot and are still looking for an ideal solution. Product protection is most important and of course it needs recognition value. Ideally, the packaging will also consist of mycelium at some point.

On your website you work a lot with pictures of mushrooms, i.e. the fruiting bodies known to all – not of the mycelium. Is this important for recognition and positive emotions towards what is actually a new and unknown product?

Yes, for one thing it does, but it doesn’t taste or look like mushroom, so it can’t stay too close to the familiar mushroom. However, that is really our base.

Feel free to get in touch if you need help with packaging design! And thanks for the glimpses into the realm of Mushlabs!